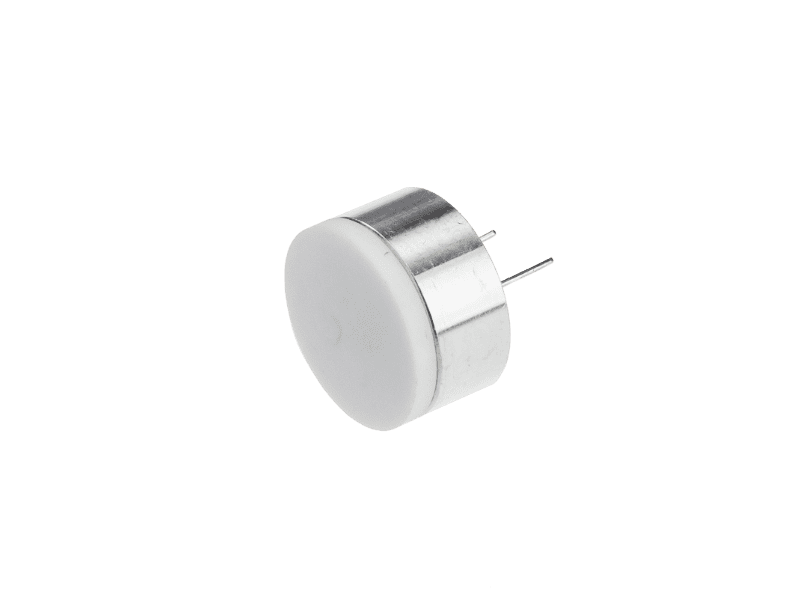

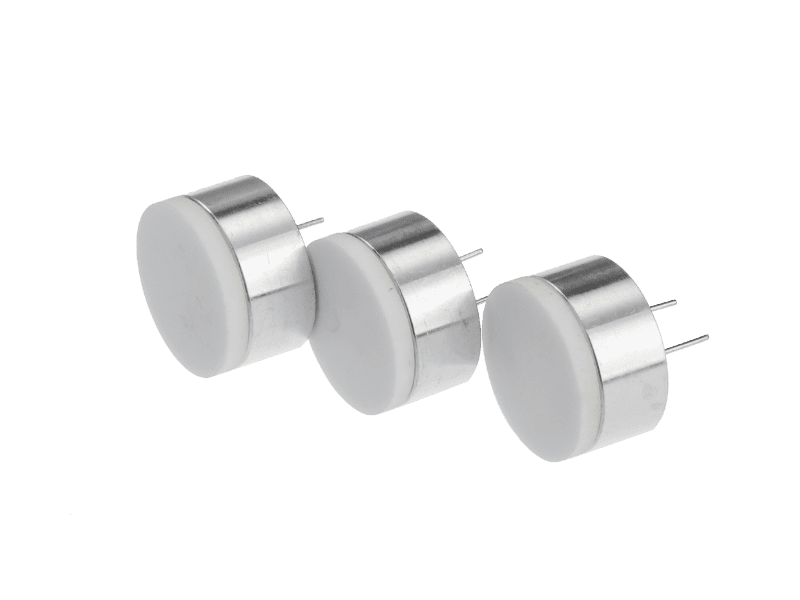

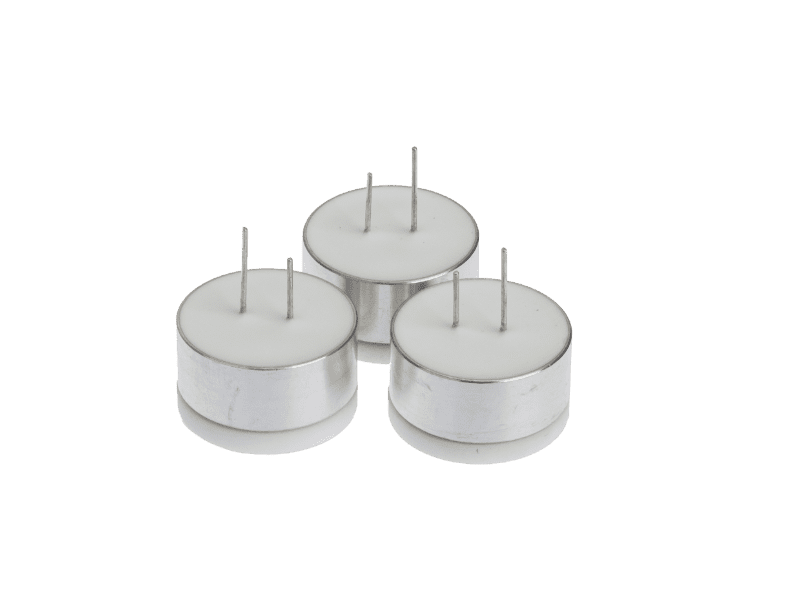

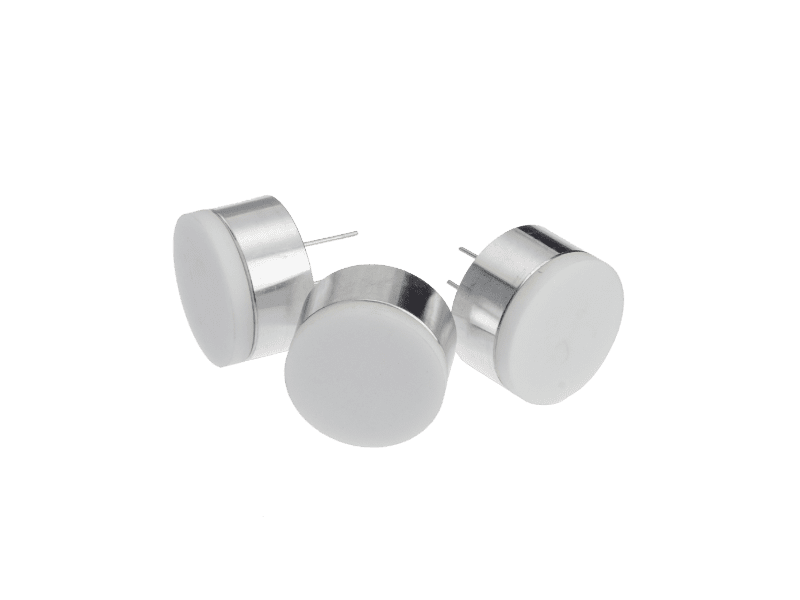

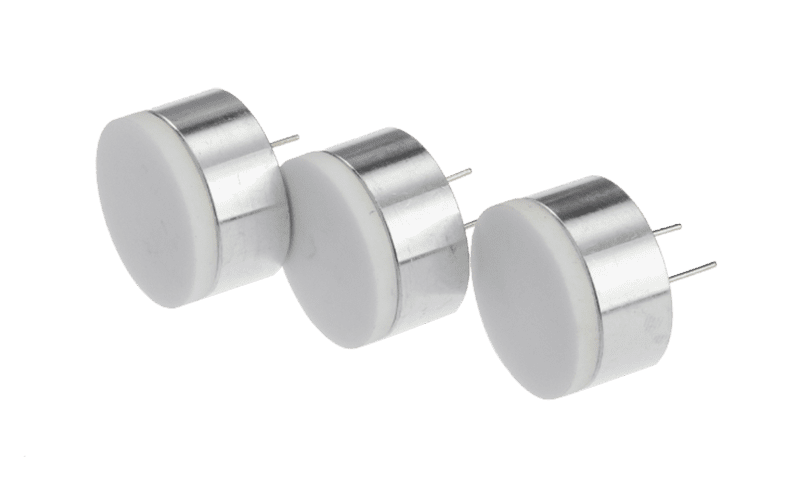

ISU200-18.6TRBZ

200kHz High-Frequency Ultrasonic Ranging Sensor for Roll Diameter Control

High Frequency, Superior Sensitivity, Waterproof Design, Compact Structure, Proven Reliability, Easy Integration, Industrial Applications, Roll Diameter Control

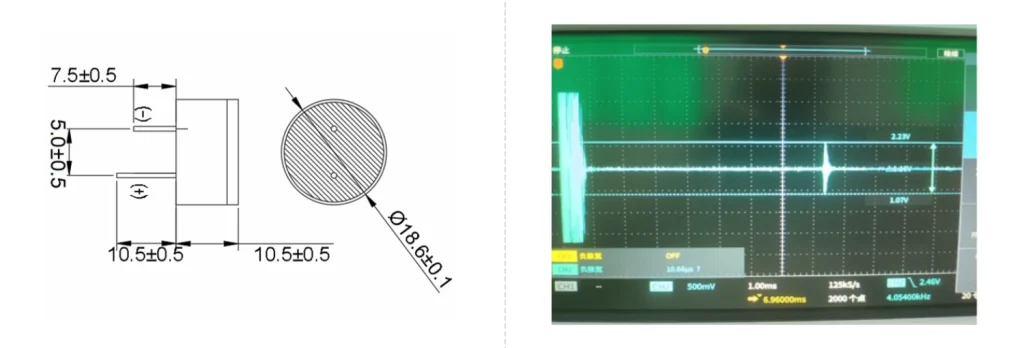

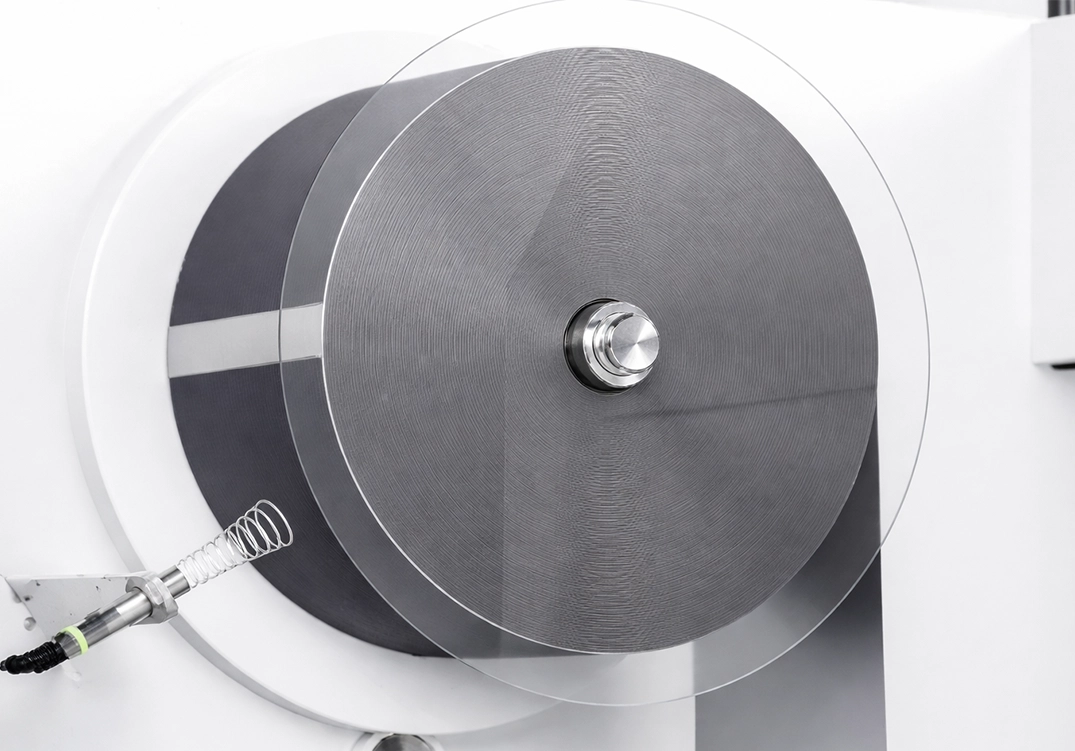

The ISU200-18.6TRBZ High-Frequency Ultrasonic Ranging Sensor is specifically designed for accurate roll diameter control in manufacturing environments. This sophisticated sensor operates at a frequency of 200kHz, providing rapid and precise distance measurements critical for monitoring roll sizes in various processes.

Its high sensitivity and excellent signal-to-noise ratio ensure consistent and reliable performance, even in challenging industrial conditions. The compact and lightweight design of the sensor allows for straightforward integration into existing systems, minimizing installation time and costs. Furthermore, its waterproof and sealed construction guarantees durability and functionality in wet or dusty environments, making it ideal for a range of applications.

This ultrasonic sensor is instrumental in roll diameter control, enabling manufacturers to maintain product quality by ensuring that materials meet stringent specifications. With its ability to operate effectively across a wide temperature range, the 200kHz ultrasonic sensor stands out as a vital tool in automated systems, quality assurance processes, and material handling operations.