I.Introduction

In industrial automation and process control, selecting the right sensing technology is often the difference between stable operation and persistent measurement problems. False readings, unexpected downtime, and frequent recalibration are rarely caused by sensor defects alone, but more often by a mismatch between the sensing principle and the real‑world application environment.

This challenge commonly surfaces when engineers evaluate the difference between ultrasonic and photoelectric sensor technologies. At a fundamental physical level, the distinction is simple: one “listens” using high‑frequency sound waves, while the other “sees” using light. Photoelectric sensors depend on reflected or interrupted light—typically infrared or laser—whereas ultrasonic sensors emit acoustic pulses and determine distance based on echo return time. Because of this, optical performance is closely tied to surface reflectivity and transparency, while ultrasonic detection remains largely independent of color, brightness, or optical properties.

Although photoelectric sensing is widely adopted across industrial automation sensors, many demanding applications—such as transparent object detection, non‑contact liquid level measurement, dusty production areas, and outdoor installations—expose the inherent limitations of light‑based detection. In these scenarios, ultrasonic sensing often proves to be the more robust and application‑tolerant solution.

II. The Basics: How They Work

Understanding the working principle behind each sensing technology is essential before comparing performance, cost, or application suitability. While ultrasonic and photoelectric sensors are often grouped together in catalogs, they are based on entirely different physical mechanisms.

2.1 Photoelectric (Optical) Sensors: Detection by Light

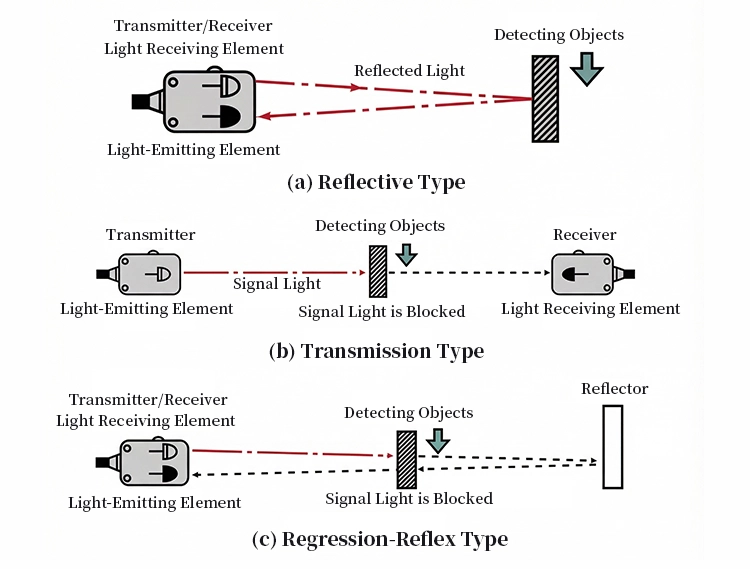

Photoelectric sensors operate by emitting a beam of light—commonly infrared or laser—and analyzing how that light behaves after leaving the emitter. Depending on the configuration, detection is achieved when the light is reflected back from a target or interrupted between an emitter and a receiver.

Because light is the sensing medium, optical performance is inherently tied to optical properties of the target and environment:

- Surface reflectivity

- Color and brightness

- Transparency or translucency

- Ambient light interference

Highly reflective objects can cause signal saturation, while dark or matte surfaces may absorb light. Transparent materials such as glass or clear plastic can allow the beam to pass through entirely. These limitations are not design flaws; they are a direct consequence of how light interacts with matter.

2.3 Ultrasonic Sensors: Detection by Sound (Time of Flight)

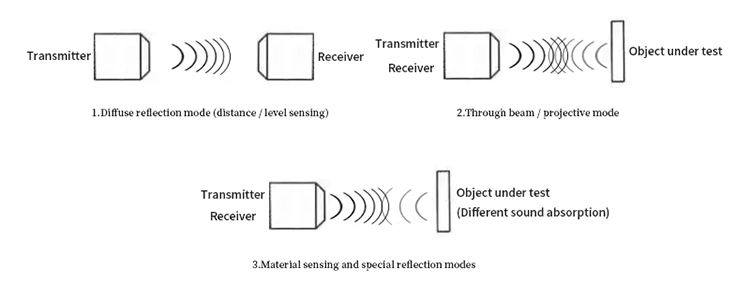

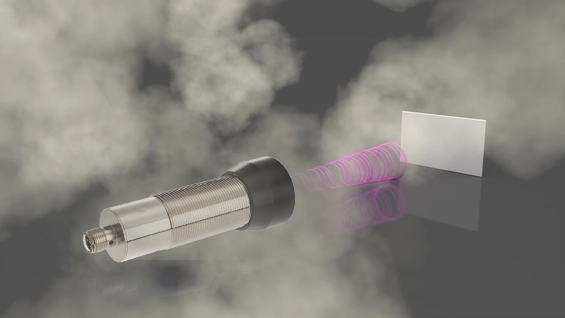

Ultrasonic sensors work on a fundamentally different principle. Instead of light, they emit high frequency sound waves—typically above 40 kHz—and measure the time it takes for the echo to return after reflecting off an object. This is known as the Time of Flight (ToF) method. Click to learn more about how it works.

Distance = Sound Speed × Echo Time

2

Ultrasonic Sensor Operating Modes:

Because ultrasonic detection relies on acoustic reflection, it is largely independent of an object’s color, transparency, or optical appearance. As long as the target presents a physical surface capable of reflecting sound, it can be detected reliably.

This is the key technical reason why ultrasonic sensors excel in applications where optical sensing struggles—such as detecting clear glass, black rubber, liquids, or objects covered in dust or mist.

2.4 Ultrasonic vs Optical Sensor: A Fundamental Trade off

From a physics standpoint, the choice between an ultrasonic and an optical sensor is a trade off between speed and environmental tolerance:

- Light travels extremely fast, allowing optical sensors to achieve microsecond level response times.

- Sound travels much slower, resulting in millisecond level response times for ultrasonic sensors.

However, this slower propagation also enables ultrasonic sensors to be far more forgiving in complex environments. Rather than depending on surface reflectance or contrast, ultrasonic sensing depends on geometry and distance—making it inherently more stable across changing materials and lighting conditions.

This fundamental difference in working principle explains most of the real world performance gaps engineers encounter when comparing ultrasonic and photoelectric solutions.

III. Quick Comparison Table: Ultrasonic vs. Photoelectric Sensors

When engineers compare sensing technologies, long explanations are useful—but clear side by side data often provides the fastest insight. The table below summarizes the most important technical differences between ultrasonic and photoelectric sensors, based on real world industrial performance rather than datasheet ideals.

| Feature | Photoelectric Sensor | 超声波传感器 |

|---|---|---|

| Sensing Medium | Light (Infrared / Laser) | Sound (High frequency ultrasound) |

| 工作原理 | Light reflection or beam interruption | Time of Flight (ToF) echo measurement |

| Target Material Dependence | Color and surface dependent | Material independent (solid surfaces) |

| Detecting Black Objects | Unreliable (Diffuse mode) / Reliable (Through-beam mode) | Stable and reliable |

| Transparent Object Detection | Frequently fails (glass, clear film) | Excellent performance |

| Environment Sensitivity | Affected by dust, mist, ambient light | Largely immune to dust and lighting |

| Outdoor Performance | Can be disturbed by sunlight | Strong sunlight immunity |

| Typical Detection Area | Point detection (narrow beam) | Area detection (defined beam angle) |

| Sensor Response Time Comparison | Very fast (µs level) | Moderate (ms level) |

| Detection Range Stability | Varies with surface reflectivity | Stable across different targets |

| Cost Comparison | Low to high (laser increases cost) | Cost effective overall |

| Maintenance Requirement | Lens cleaning often required | Minimal (no optical window) |

What This Comparison Really Tells Us

At a glance, photoelectric sensors appear attractive due to their speed and compact optical design. However, the table also highlights why ultrasonic sensors are often considered the most versatile option among proximity sensor types, especially when operating conditions are less than ideal.

Rather than relying on how an object looks to light, ultrasonic sensors depend on physical presence and distance. This makes them particularly well suited for applications involving:

- Mixed materials on the same production line

- Transparent or highly absorbent surfaces

- Dusty, humid, or outdoor environments

- Non-contact distance and level measurement

The response time difference is real and should be acknowledged. Optical sensors operate in microseconds, while ultrasonic sensors respond in milliseconds. For ultra high speed counting, light based detection remains the better choice. However, in most industrial automation scenarios where reliability outweighs raw speed, ultrasonic sensing delivers more consistent results.

IV. When to Choose Ultrasonic Sensors (Top 3 Scenarios)

While both ultrasonic and photoelectric technologies have their place, certain application scenarios consistently expose the limitations of light based detection. In these cases, ultrasonic sensors are not just an alternative—they are often the more reliable engineering choice.

4.1 The “Invisible” Problem: Transparent Object Detection

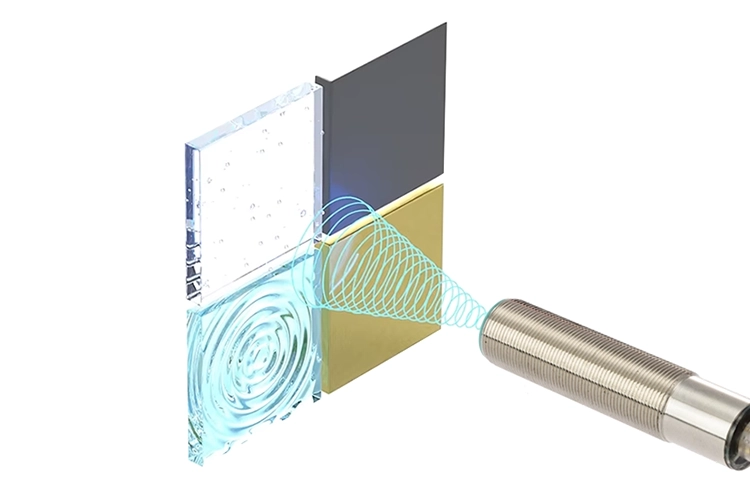

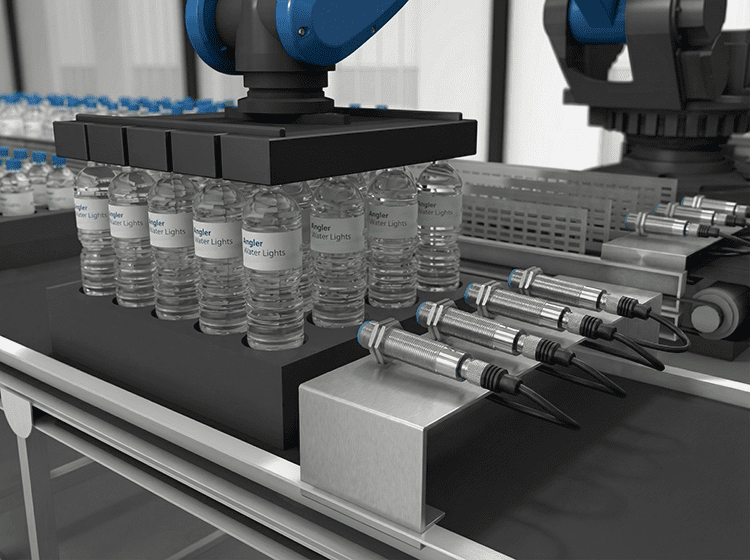

One of the most common failure points for optical sensing is the detection of transparent objects. Glass, clear plastic bottles, and thin plastic films allow light to pass through with minimal reflection, making reliable detection difficult or impossible for photoelectric sensors.

This is where ultrasonic sensing fundamentally differs. Sound waves do not pass through rigid transparent materials the way light does; they reflect off physical surfaces. As a result, ultrasonic sensors detect a glass panel or bottle just as easily as an opaque object at the same distance.

For applications such as bottle presence detection, packaging film control, or clear container positioning, a transparent object detection sensor based on ultrasonic technology provides consistent results without special reflectors or complex optical adjustments. High frequency ultrasonic probes, in particular, offer improved resolution and stability when detecting thin or smooth transparent targets.

4.2 Surviving the Elements: Dusty and Outdoor Environments

Dust, powder, mist, and outdoor exposure are persistent challenges in industrial sensing. Photoelectric sensors rely on clean optical paths; once dust accumulates on the lens, signal strength drops and false readings become inevitable. Regular cleaning is often required, increasing maintenance costs and downtime.

Ultrasonic sensors, by contrast, operate without optical windows. The vibrating surface of the ultrasonic transducer naturally resists dust accumulation—a phenomenon often referred to as a self cleaning effect. This inherent robustness allows many ultrasonic sensors to easily maintain IP67 or IP68 ratings, ensuring reliable operation even in washdown areas where optical lenses would quickly cloud over. Because detection is acoustic rather than optical, performance remains stable even when the sensor face is exposed to airborne particles or splashing liquids.

This makes ultrasonic technology a strong candidate for any sensor for dusty environment applications, as well as for outdoor proximity sensor and distance measurement tasks. Additionally, ultrasonic sensors are inherently immune to sunlight interference, a common source of false triggering for optical sensors installed outdoors.

4.3 The “Black Hole”: Color and Surface Independence

Another well known limitation of photoelectric sensors—specifically those using diffuse mode—is their sensitivity to color. Black rubber, matte plastic, and other light absorbing materials reflect very little optical energy back to the receiver. While through-beam photoelectric sensors can detect black objects by blocking the light path, the more common and cost-effective diffuse sensors are often pushed to the edge of their detection limits on dark surfaces.Ultrasonic sensors are completely unaffected by color or brightness. Detection depends solely on the physical presence and geometry of the target. Whether the object is black, white, glossy, or textured makes no practical difference.

For applications involving detecting black objects or mixed color materials on the same line, ultrasonic sensing eliminates the need for constant sensitivity tuning and reduces the risk of intermittent detection failures caused by surface variation.

Summary of Ideal Ultrasonic Use Cases

Ultrasonic sensors are especially well suited for applications that involve:

- Transparent or translucent objects

- Dusty, humid, or outdoor environments

- Black, dark, or optically absorbent materials

- Situations where detection reliability matters more than microsecond level speed

These scenarios represent a large portion of real world industrial sensing challenges—and they explain why ultrasonic technology remains a preferred solution in environments where optical sensors struggle.

V. When to Stick with Photoelectric Sensors

Despite the robustness of ultrasonic sensing, it is not a universal solution. There are specific scenarios where photoelectric sensors remain the more appropriate and technically sound choice. Understanding these boundaries is critical for making correct engineering decisions.

5.1 High Speed Detection and Counting

Photoelectric sensors excel in applications that demand extremely fast response times. Because light travels orders of magnitude faster than sound, optical sensors can react in microseconds, making them ideal for high speed counting, positioning, and edge detection.

Typical examples include:

- High speed conveyor counting

- Small part detection on fast moving lines

- Precise trigger timing in packaging and labeling machines

In these cases, the millisecond level response time of ultrasonic sensors may introduce unacceptable latency, even if detection reliability remains high.

5.2 Very Small Targets and Fine Features

Ultrasonic sensors emit sound waves with a finite beam angle. While this enables area detection, it also limits spatial resolution. Very small objects, thin edges, or fine features may not reflect enough acoustic energy to generate a stable echo.

Photoelectric sensors—especially laser based models—offer highly focused beams capable of detecting:

- Thin wires or pins

- Sharp edges

- Small gaps or slots

When sub millimeter precision is required, optical sensing is often the only practical option.

5.3 Close Range Applications Below the Blind Zone

All ultrasonic sensors have a blind zone: a minimum distance below which reliable detection is not possible due to transducer ringing after emission. Objects that pass too close to the sensor face may fall inside this dead zone.

Photoelectric sensors do not suffer from this limitation and can detect objects at very short distances, sometimes down to a few millimeters. For applications requiring consistent detection at close range, optical sensors are often the safer choice.

5.4 Controlled, Clean Environments

In clean, well lit indoor environments where:

- Dust and moisture are minimal

- Targets are opaque and uniform

- Ambient lighting is stable

photoelectric sensors can perform reliably with minimal maintenance. In such conditions, their faster response and compact design often outweigh the robustness advantages of ultrasonic sensing.

Engineering Takeaway

Choosing between ultrasonic and photoelectric sensors is not about which technology is “better,” but which is better suited to the application constraints.

- If speed, fine resolution, or very short detection distances are critical, photoelectric sensing is often the correct choice.

- If environmental tolerance, material independence, or long term stability matter more, ultrasonic sensing typically offers superior performance.

Recognizing these trade offs is what separates trial and error selection from sound engineering design.

VI. Key Selection Criteria Engineers Often Overlook

Datasheets provide necessary specifications, but they rarely capture the full complexity of real world sensing conditions. Many sensor selection failures occur not because the wrong technology was chosen in principle, but because subtle application factors were overlooked during design and installation.

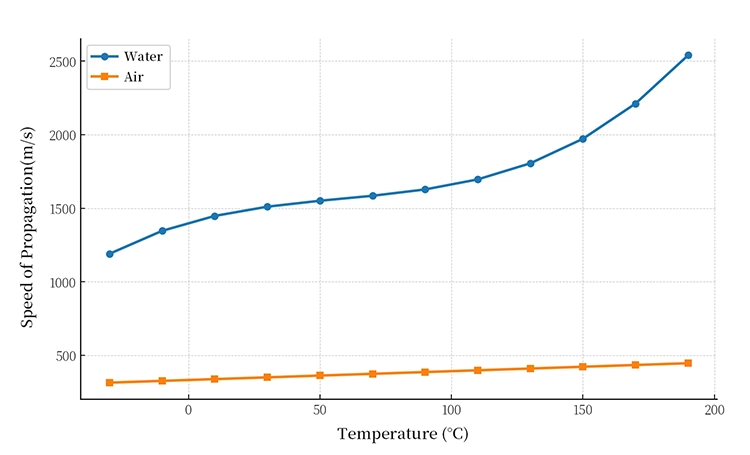

6.1 Temperature Effects: Why Sound Speed Matters

Ultrasonic sensors calculate distance based on the speed of sound in air, which is temperature dependent. As temperature increases, sound travels faster; as it decreases, sound slows down. This directly affects distance accuracy.

v ≈ 331 + 0.6T (m/s, T in °C)

In environments with large temperature variations—such as outdoor installations or near furnaces—this effect can introduce measurable error if not compensated.

High quality ultrasonic sensors address this in one of two ways:

- Built in temperature compensation

- External temperature reference for correction

Ignoring temperature influence can lead to drifting distance readings, especially in long range or level measurement applications.

6.2 Installation Angle and Target Geometry

Ultrasonic sensing depends on specular reflection of sound waves. Flat targets positioned perpendicular to the sensor face reflect echoes directly back, producing strong signals. However, angled or irregular surfaces can deflect sound away from the receiver.

Common issues include:

- Sloped container walls in level measurement

- Curved or cylindrical targets

- Objects approaching the sensor at an angle

In these cases, detection range may be reduced even if the object is well within the nominal sensing distance. Proper mounting angle, or selecting a sensor with an appropriate beam width, often matters more than increasing output power.

6.3 Beam Angle vs. Detection Area

Unlike optical sensors with narrow, well defined beams, ultrasonic sensors operate with a conical detection zone. This can be an advantage or a limitation, depending on the application.

- Wide beam angle:

- Better for area detection and level measurement

- More tolerant of target position variation

- Narrow beam angle:

- Improved selectivity

- Reduced risk of false echoes from nearby structures

Engineers sometimes focus only on maximum range, overlooking how surrounding objects—such as tank walls, brackets, or conveyors—can generate unwanted echoes within the beam.

6.4 Blind Zone and Mechanical Clearance

Every ultrasonic sensor has a minimum detection distance, often referred to as the blind zone. Objects entering this zone cannot be reliably detected due to transducer ringing after emission.

This becomes critical in:

- Short range positioning

- Compact mechanical designs

- Retrofits where mounting space is limited

Failing to account for the blind zone can result in intermittent detection loss that is difficult to diagnose during commissioning.

6.5 Environmental Noise and Cross Talk

In multi sensor installations, especially when multiple ultrasonic sensors operate in close proximity, acoustic cross talk can occur. One sensor may receive echoes from another, leading to unstable readings.

Mitigation strategies include:

- Time multiplexed triggering

- Frequency separation

- Physical shielding or spacing

This consideration is often absent from early design discussions but becomes critical in dense sensor layouts.

Engineering Insight

Effective sensor selection goes beyond choosing between ultrasonic and photoelectric technologies. It requires understanding how physics, installation, and environment interact over time.

Engineers who account for temperature variation, beam geometry, mounting constraints, and acoustic interference upfront can avoid many of the reliability issues commonly blamed on “sensor quality.”

VII. Conclusion

After comparing working principles, performance trade offs, and real world application constraints, one conclusion becomes clear: there is no universally “best” sensor—only the most appropriate sensing technology for a given task.

Rather than starting with a product category, engineers should begin with application conditions and failure risk analysis.

Start with the Environment

The operating environment is often the strongest determining factor in sensor selection.

- If the application involves dust, mist, humidity, or outdoor exposure, ultrasonic sensing offers greater long term stability.

- If ambient light, glare, or surface contamination cannot be tightly controlled, light based detection becomes inherently less predictable.

In harsh or variable environments, robustness usually outweighs raw speed.

Evaluate the Target, Not Just the Distance

Target properties directly influence detection reliability.

- Transparent, black, or optically inconsistent objects favor ultrasonic detection.

- Very small features, sharp edges, or fine details favor photoelectric or laser based sensing.

If multiple target materials are present on the same line, material independent detection can significantly reduce tuning effort and downtime.

Consider Time and Precision Requirements

Response time and resolution should be evaluated honestly.

- Choose photoelectric sensors when microsecond level response or sub millimeter precision is mandatory.

- Choose ultrasonic sensors when millisecond level response is acceptable and detection stability is more critical than speed.

Over specifying speed often leads to unnecessary complexity without real performance benefits.

Account for Installation and Long Term Operation

Reliable sensing is not only about initial performance, but also about how the system behaves months or years after installation.

- Blind zones, beam angles, and mounting geometry must be considered early.

- Maintenance requirements—such as lens cleaning or recalibration—should be factored into total cost of ownership.

A sensor that works “on day one” but drifts over time is rarely the optimal choice.

Final Engineering Perspective

Ultrasonic and photoelectric sensors represent two fundamentally different approaches to non contact detection: one based on sound, the other on light. Understanding their physical limits and strengths allows engineers to select technologies proactively, rather than troubleshooting failures after installation.

In applications where environmental tolerance, material independence, and long term stability are critical, ultrasonic sensing remains a highly reliable and widely adopted solution. Where speed, fine resolution, and close range precision dominate, photoelectric sensing continues to play an essential role.

The most effective designs do not favor one technology by default—they match sensing principles to real world conditions.

FAQ

Q1: Are ultrasonic sensors more accurate than photoelectric sensors?

A1: Accuracy depends on how it is defined and on the application. Photoelectric sensors generally offer higher positional precision and faster response times, especially in short range, high speed applications. Ultrasonic sensors, on the other hand, provide more consistent distance accuracy across different target materials because they are not affected by color, transparency, or reflectivity. In practice, ultrasonic sensors often deliver more reliable measurements in variable environments, while photoelectric sensors excel in controlled conditions requiring fine resolution.

Q2: Can ultrasonic sensors detect transparent objects reliably?

A2: Yes. Detecting transparent objects is one of the strongest advantages of ultrasonic sensing. Glass, clear plastic, and transparent films reflect sound waves even when they allow light to pass through. As a result, ultrasonic sensors can detect transparent targets without special reflectors or optical alignment, unlike many photoelectric solutions.

Q3: Do ultrasonic sensors work outdoors?

A3: Ultrasonic sensors are well suited for outdoor use because they are immune to ambient light and sunlight interference. However, environmental factors such as temperature, wind, and heavy rain can influence sound propagation. For outdoor installations, sensors with temperature compensation and proper mounting are recommended to maintain measurement stability.

Q4: Why do ultrasonic sensors have a blind zone?

A4: The blind zone exists because the ultrasonic transducer continues to vibrate briefly after emitting a sound pulse. During this ringing period, the sensor cannot reliably receive echoes from very close targets. This is a physical limitation of ultrasonic transducers, not a design flaw. Applications requiring detection at very short distances may be better served by photoelectric sensors.

Q5: Can ultrasonic sensors replace photoelectric sensors entirely?

A5: No. Ultrasonic and photoelectric sensors are complementary technologies rather than direct replacements. Photoelectric sensors remain the better choice for ultra high speed detection, very small targets, and applications requiring millimeter or sub millimeter resolution. Ultrasonic sensors are preferred when environmental robustness, material independence, and long term reliability are more important than speed or fine detail.

Q6: Are ultrasonic sensors affected by dust or dirt?

A6: Ultrasonic sensors are far less affected by dust than photoelectric sensors because they do not rely on optical lenses. In many cases, the vibration of the sensor face helps prevent dust accumulation. This makes ultrasonic sensors a common choice in dusty, powder filled, or dirty industrial environments.

Q7: How does temperature affect ultrasonic sensor performance?

A7: The speed of sound in air changes with temperature, which can affect distance measurement accuracy. High quality ultrasonic sensors compensate for this automatically using built in temperature measurement or correction algorithms. In environments with large temperature fluctuations, temperature compensation is essential for stable results.

Q8: Can multiple ultrasonic sensors interfere with each other?

A8: Yes, acoustic cross talk can occur when multiple ultrasonic sensors operate close together. This can usually be mitigated through timing control, frequency separation, or proper sensor spacing. In multi sensor systems, coordination strategies should be considered during system design.

Q9: Are ultrasonic sensors suitable for liquid level measurement?

A9: Ultrasonic sensors are widely used for non contact liquid level measurement. They work well with most liquids and are unaffected by color or transparency. However, heavy foam, strong turbulence, or angled liquid surfaces can weaken echo signals and should be evaluated during selection.

Q10: How should engineers choose between ultrasonic and photoelectric sensors?

The most effective approach is to start with the application environment. A simple ‘Field Engineer’s Rule of Thumb’ is: If the environment is clean and you can see the object clearly, use Photoelectric (Optical) sensors for speed. If the environment is dirty, the lighting is poor, or the object is invisible (clear glass), use Ultrasonic sensors for reliability. Always match the sensing principle to the specific failure risks of your production line.